Production

The main scope of activity

The main scope of activity of the Tanks Department of NIWA company is the execution and repairs of pressure equipment and storage tanks for the chemical, petrochemical, energy and food industries, such as:

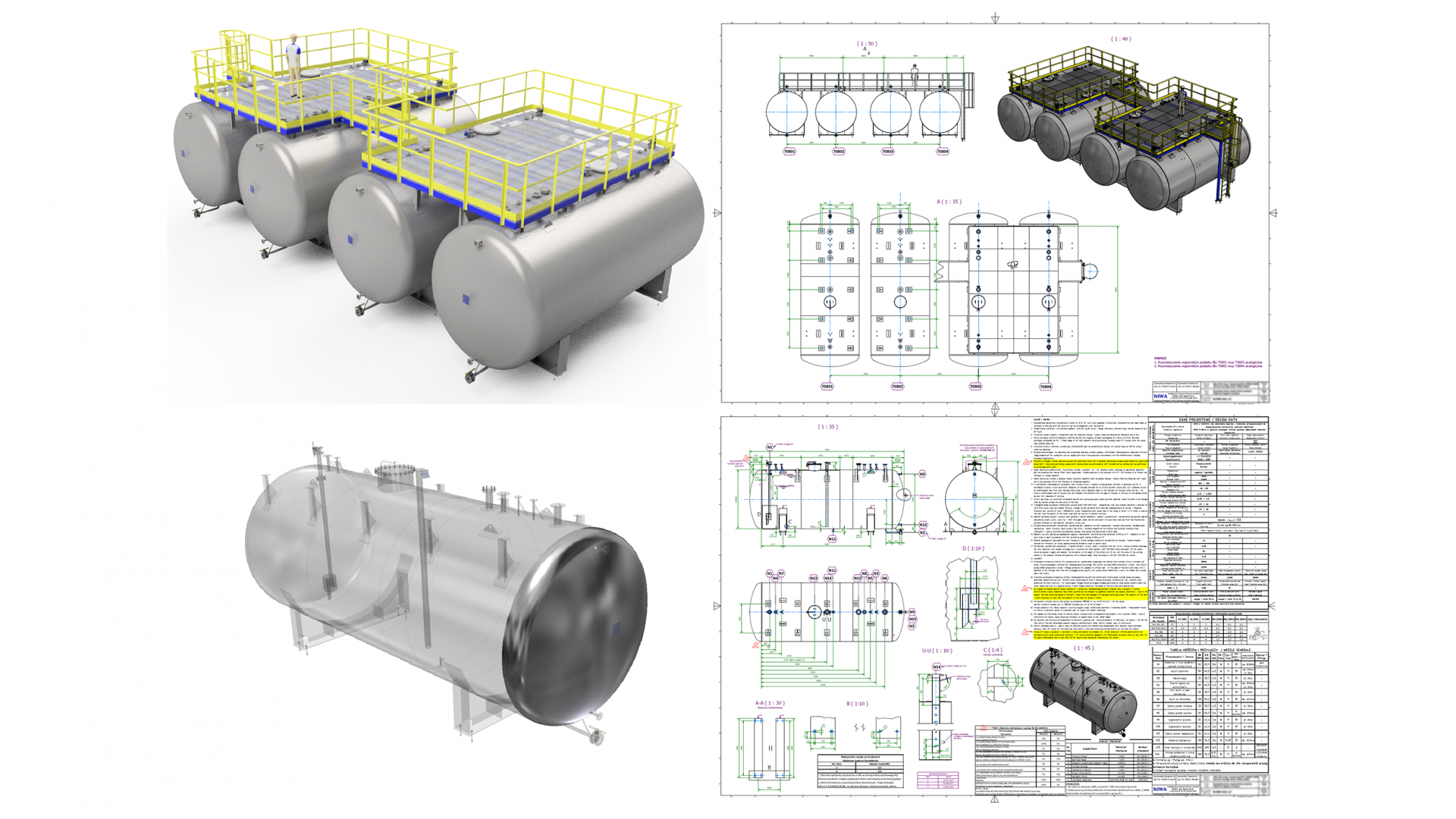

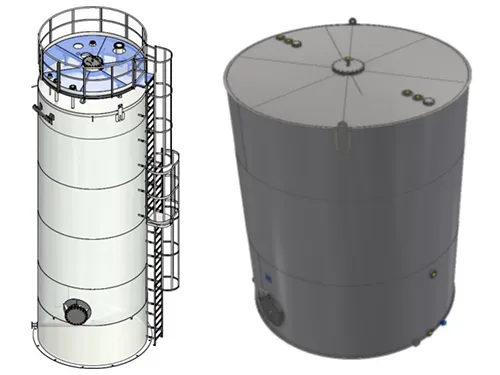

STORAGE AND PROCESS TANKS

-

ABOVE GROUND STORAGE TANKS

-

UNDERGROUND STORAGE TANKS

-

PRESSURE STORAGE TANKS

-

NON-PRESSURE STORAGE TANKS

PRESSURE APPARATUS

-

FILTERS

-

ABSORBERS

-

SEPARATORS

-

REACTORS

HEAT EXCHANGERS

-

SHELL AND TUBE HEAT EXCHANGER

-

HEATERS

-

EVAPORATOR HEAT EXCHANGERS

-

HEAT EXCHANGERS CONDENSERS

-

STEAM GENERATOR

COLUMNS

-

DISTILLATION COLUMNS

-

RECTIFICATION COLUMNS

-

ABSORPTION COLUMNS

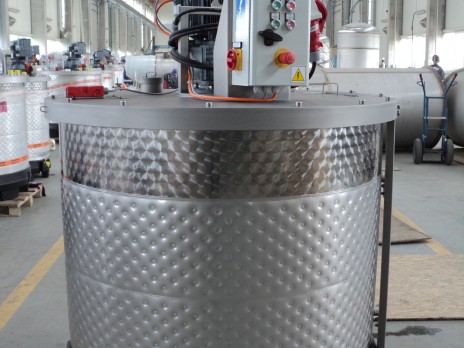

TANKS FOR FOOD INDUSTRY

-

FERMENTOR TANK

-

MIXERS

-

BREW KETTLE

-

LAUTER TANK

-

SPIRIT TANK

WE MAKE THE ABOVE MENTIONED DEVICES BASED ON THE FOLLOWING REGULATIONS:

- Polish Office of Technical Inspection (UDT),

- EN13445, EN-12952 European standards and the 2014/68/EU PED Directive,

- The American Society of Mechanical Engineers (ASME)..

We are also authorized to manufacture, repair and modernize storage tanks for corrosive, toxic and flammable media.

TO CONSTRUCT THE DEVICES, WE USE THE FOLLOWING STEELS:

- carbon,

- low-alloyed,

- high-alloyed,

- high-alloy austenitic,

- duplex, superduplex, nickel.

We carry out welding works in the above-mentioned steel grades using the TIG, MIG, MAG, MMA, PAW and SAW methods; manually, semi-automatically and automatically. We have over a hundred of welding technologies in our portfolio.

Insulations

We recommend our clients to perform various types of insulation directly at the production plant using advanced technological solutions.

WE MAKE INSULATIONS, USING:

- Mineral wool,

- Armalfex Rubber Foam,

- Foam PUR,

- Foam glass „Foamglas“.

Insulation steel jacket is made in the following versions: leak proof welded, semi-tight. The materials used are stainless steel, coated sheets and aluminum.

We guarantee high quality and timely execution of contracts, thanks to which we gain the trust of a growing number of our domestic and foreign customers.